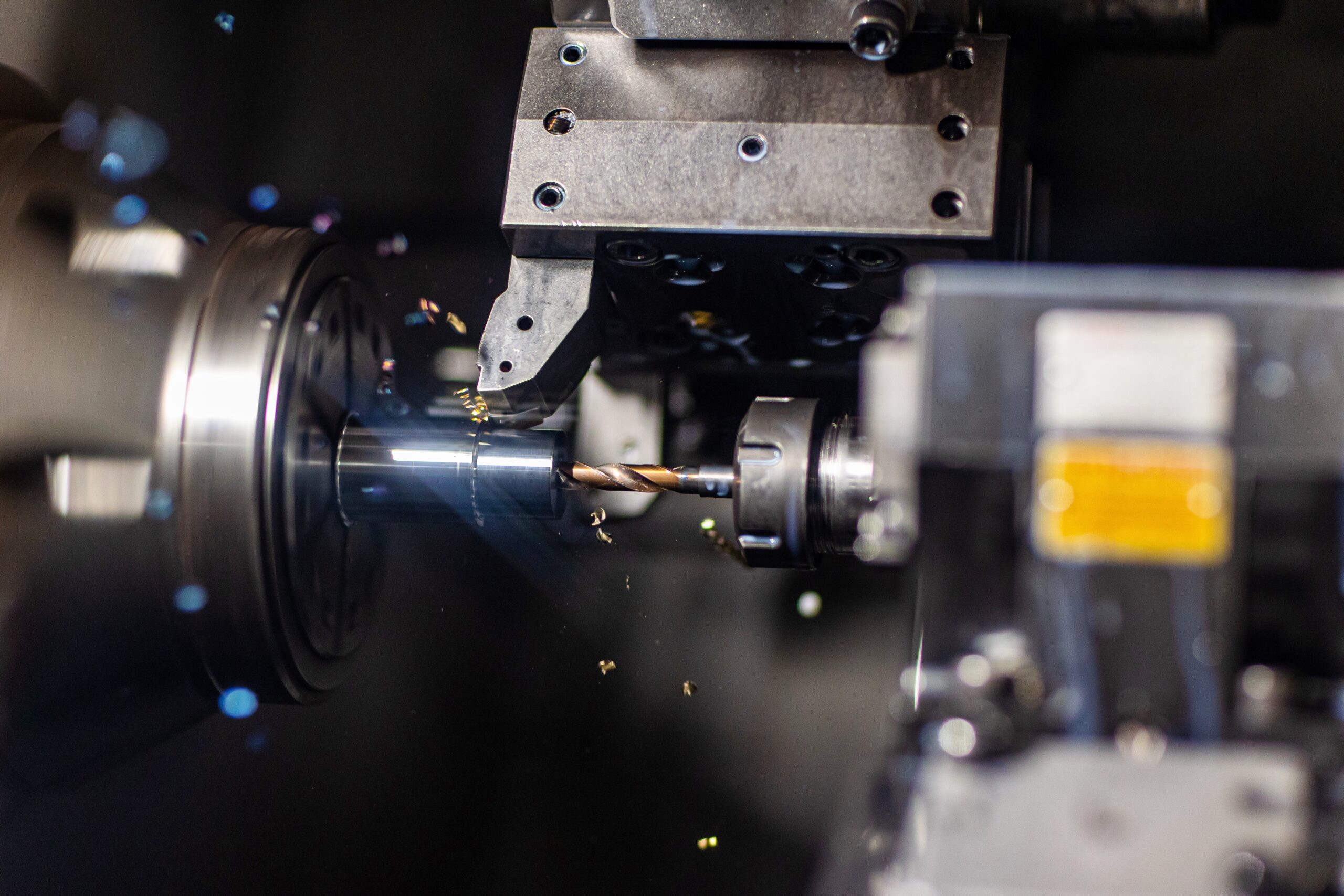

Precision CNC Machining

OurClass A machinists have experience using a variety of materials and can machine virtually any type of part including:

- Castings

- Forgings

- Extrusions

- Alloy steels

- Billet

- Bar stock

- Stainless steel

- Hastelloy

- Aluminum

- Ductile iron

- Brass

- Plastics

- Carbon steel

- Titanium

- Inconnel

- Cast iron

- Copper

- Bronze

- Composites

- Glass

- Quartz

Wide Range of Configurations

Our precision CNC machining cells leverage best-in-class equipment and technologies from Mori-Seiki, Mazak, OKK and Okuma, allowing for production runs of any size without compromising quality.

- Horizontal and vertical lathes – up to 900MM

- Vertical and Horizontal Machining Centers – up to 800 MM

- Multi-Axis Machining

- Robotic Machining

- Production Machining (with EAU over 100,000)

- Turning machines with bar-feeders and live-tooling

Our cellular machining centers utilize up to four machines in one cell that can be operated with as few as one machinist, reducing set-up and labor charges. Our machinery features high-pressure, through-tool coolant technology designed to minimize temperatures and maintain integrity, with offline programming by Mastercam.

CONTACT US to learn how Velocity Machine’s machining capabilities can provide value for your operations.

Robotic Machining

Our two Fanuc Robots Cells allow us to efficiently and economically fulfill mid-to-high volume production runs.

Our robotic cells feature one robot, two Okuma vertical turning centers and one Okuma vertical mill. These automated systems feature a conveyor system, camera to ensure part orientation and a dedicated machinist that monitors the process.

CONTACT US to learn how Velocity Machine’s precision lathe capabilities can provide value for your operations.

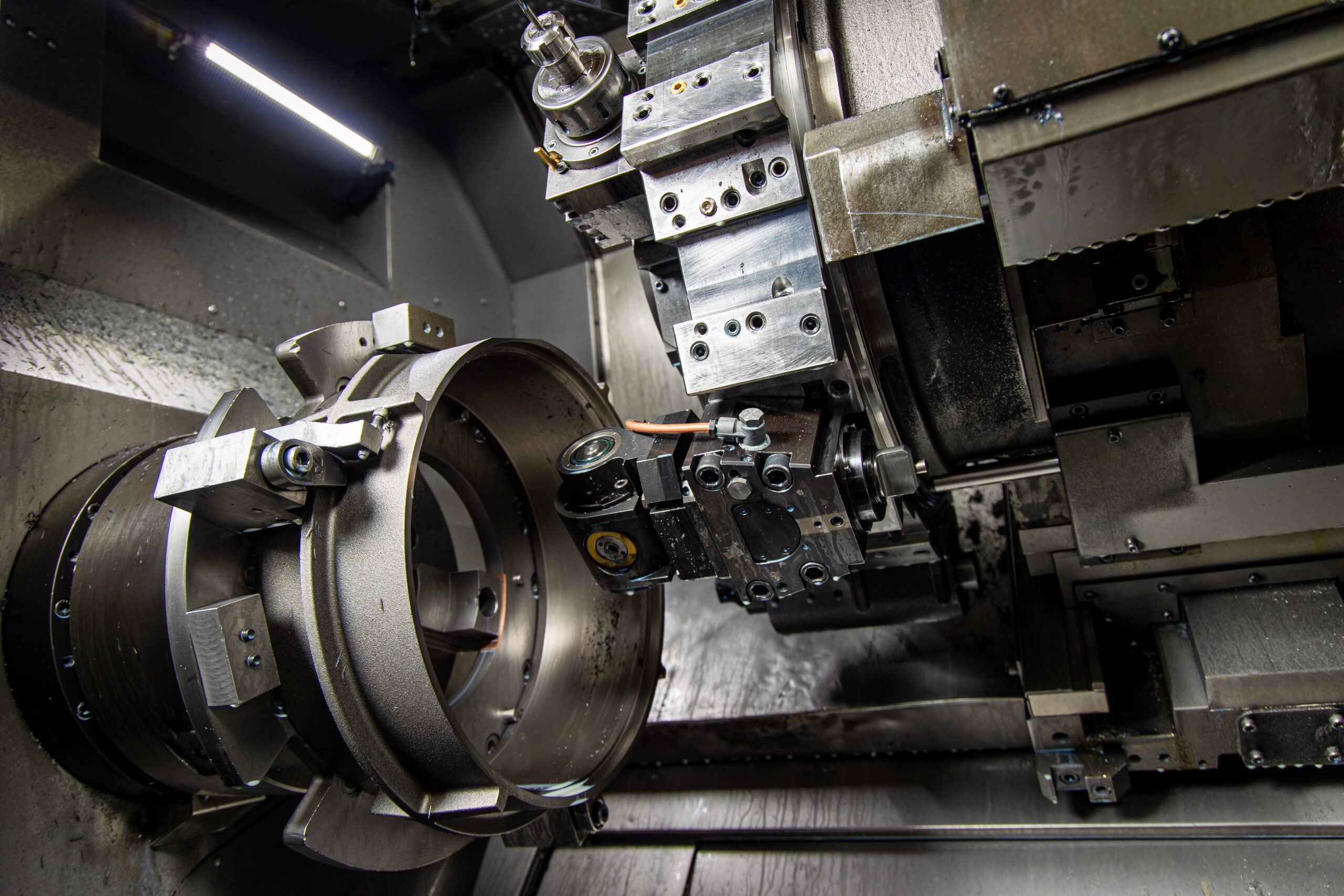

Precision Lathe (Horizontal and Vertical)

Velocity Machine’s extensive lathe department features production, bar-feed lathes, horizontal lathes and VTL lathes (vertical lathes), including production cells for the bar-fed and VTL lathes. In order to accommodate mid- to high-level production runs, our lathes offer up to 39-inch swing and 35-inch turning, with additional features including:

- Automatic bar feeders

- Live tooling

- Twin-spindle

- Twin-turret

- The ability to accept programs completed offline through Mastercam programming software

Our Mori-Seiki, Mazak, OKK and Okuma precision turning machines are the finest in the industry, which means you can depend on high-quality output every time.

Leading-Edge Technology from DMG MORI

Velocity Machine’s latest investment in advanced lathe technology is the DMG MORI NZX2000 SY800, a twin-turret, twin-spindle, high-precision and high-efficiency multi-axis turning center with an automatic bar feeder. This exceptional machine, which reduces cycle times and improves production of high-performance parts, was designed with the concept of handling the entire machining of complex parts in one place.

The BMT (built-in motor turret) enables milling at speeds of up to 12,000 RPM, with 16 live tools per turret and 32 tools per machine. Coupled with the bar feeder, loader and workpiece ejector, the machine becomes an automatic machining center.

CONTACT US to learn how Velocity Machine’s precision lathe capabilities can provide value for your operations.

Precision Milling (Horizontal and Vertical)

Velocity Machine’s horizontal and vertical precision milling machines (Mori-Seiki, Mazak, OKK and Okuma) are the best in the industry, producing high-quality output with reliable consistency for mid to high production runs.

Our Precision Milling Department features numerous standalone and cellular machines with capacity windows ranging from 400MM to 800MM. All have full fourth axis capabilities, Renishaw probes, pallet changes and offline programming by Mastercam.

CONTACT US to learn how Velocity Machine’s precision milling capabilities can provide value for your operations.